Project Goals:

Create a better paintball "Pod"

Personal Responsibilities:

Personal Project

Sketching, CAD, Prototyping, Patent Drawing, Marketing

Sketching, CAD, Prototyping, Patent Drawing, Marketing

Project Specifics:

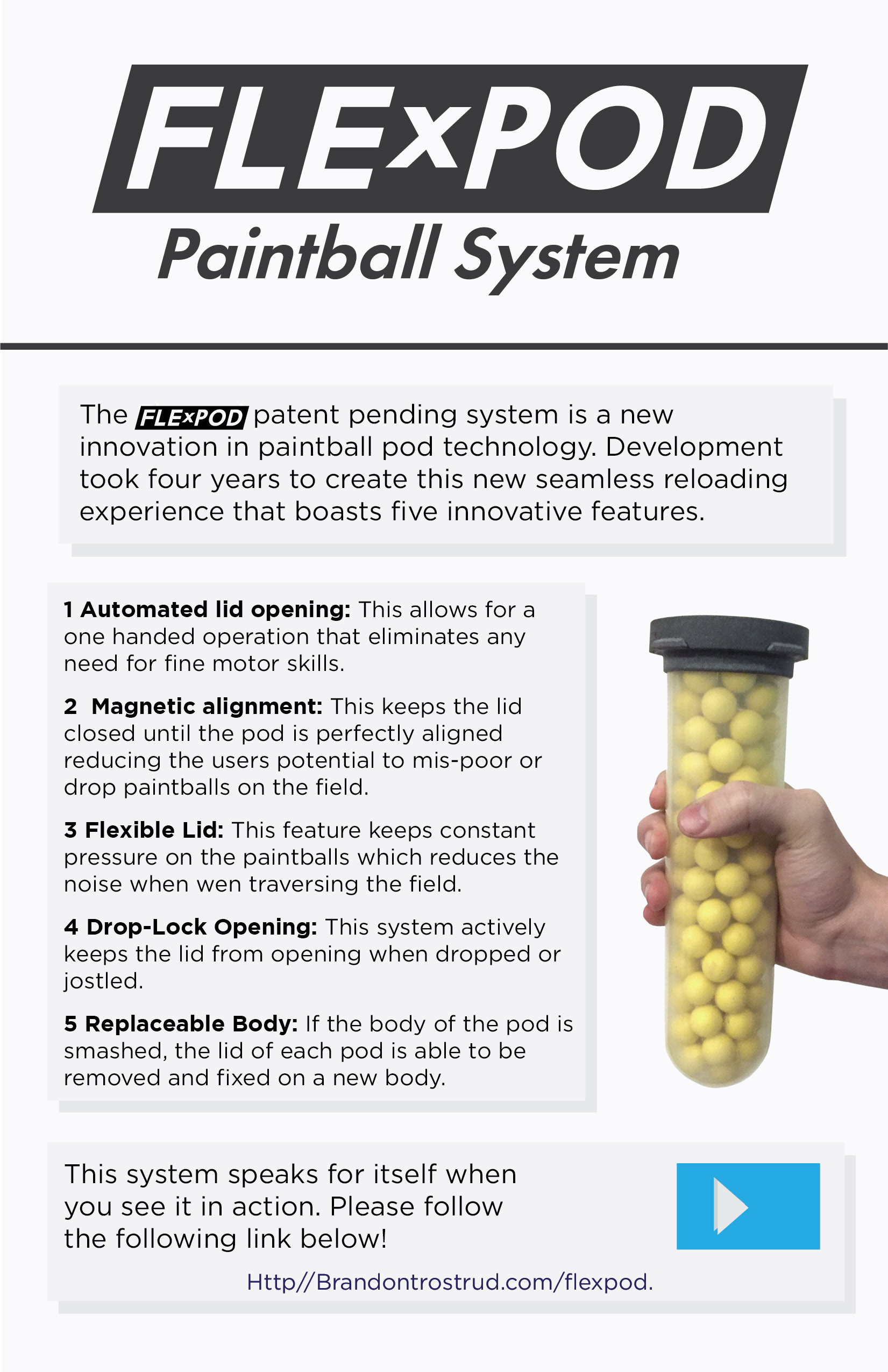

Paintball pods hold extra paintballs which are used to reload a paintball marker during play. In college, I initially came up with this idea, but it took a couple of years working professionally before I learned enough to bring it to life. I then went on to successfully sell the IP in 2019.

Currently users have to access a pod from their back while holding their paintball marker. They then open the lid to their paintball maker and to the pod itself. Once both are open, the pods contents are dumped into the paintball marker completing the reload.

For my design, I wanted to eliminate the need for any fine motor movements, and to reduce the amount of paint spilled while reloading. I accomplished this by designing a magnetic switch that aligns, unlocks, and unloads automatically. The four key milestones for the final design are illustrated below.

V1 was the first prototype that I created as a proof of concept. This design was larger to house springs, but I found by using a stretchy (spandex) opening I could remove them and save on space. The core of the mechanism uses magnets to lock and unlock the lid.

V2 took it a step further by changing out the opening material from spandex to latex. This reduced the height overall by about 50%. At this point, the base screws were also swapped for clips to reduce part count and make the design more streamlined.

V3 solved a problem where the lid would open when dropped. This was managed by making the internal mechanism more like a ratchet, which when dropped would only move one tooth over. This also aided in closing the pod.

V4 solved the last problem where the top cap was too weak to handle the stress of use. This was due to the slit that ran halfway thru the side of the body. After extensive testing, I found a solution in moving the closing latch to the interior of the lid. This removed the slit making the design stronger, and easier to mold.