Project Goals:

Design a product from the ground up to sort and load loose amination into firearm magazines.

Responsibilities:

Project Lead

Presentations, concept art, 3D models, Prototypes, Rendering

Presentations, concept art, 3D models, Prototypes, Rendering

Project Specifics:

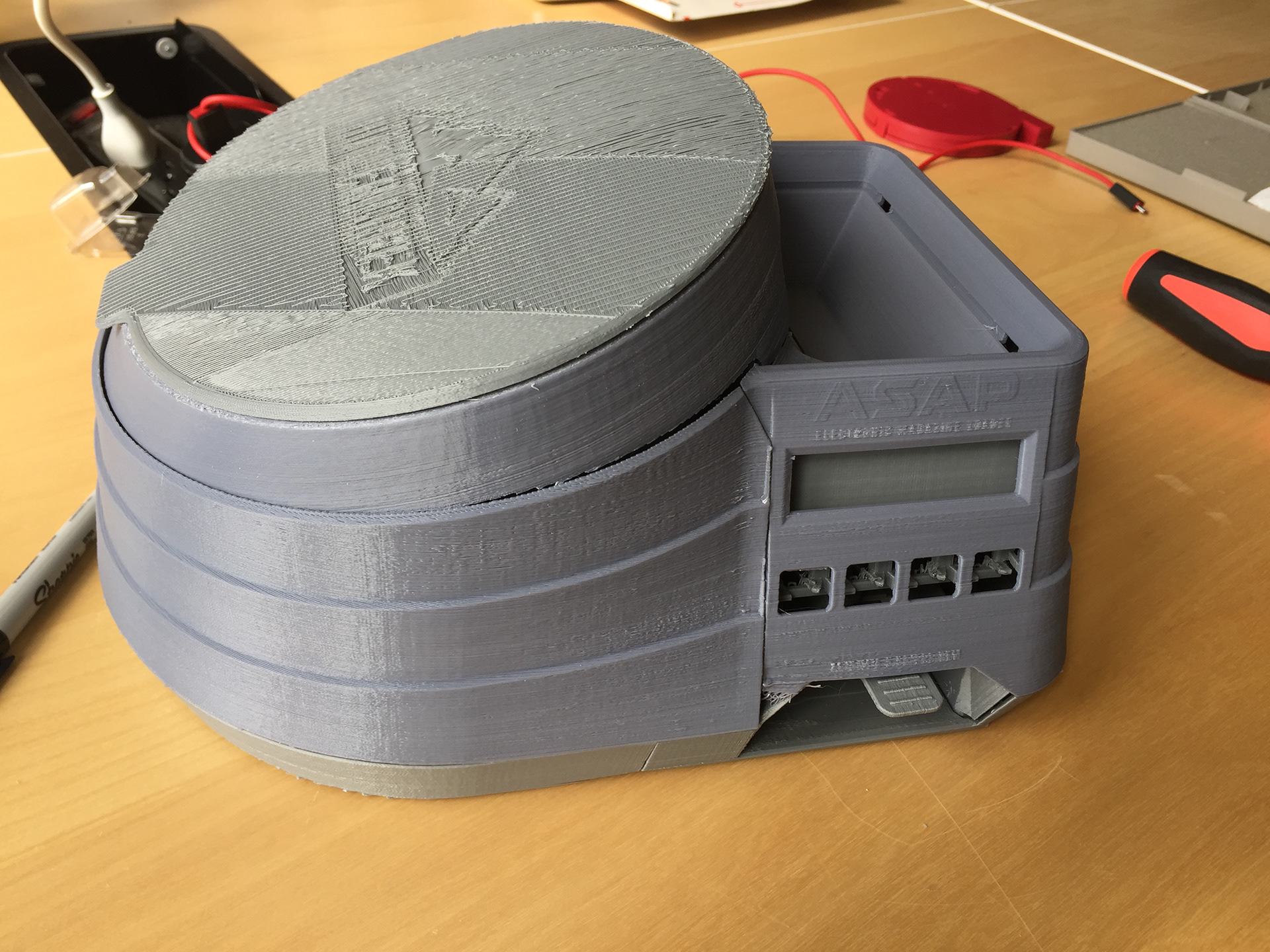

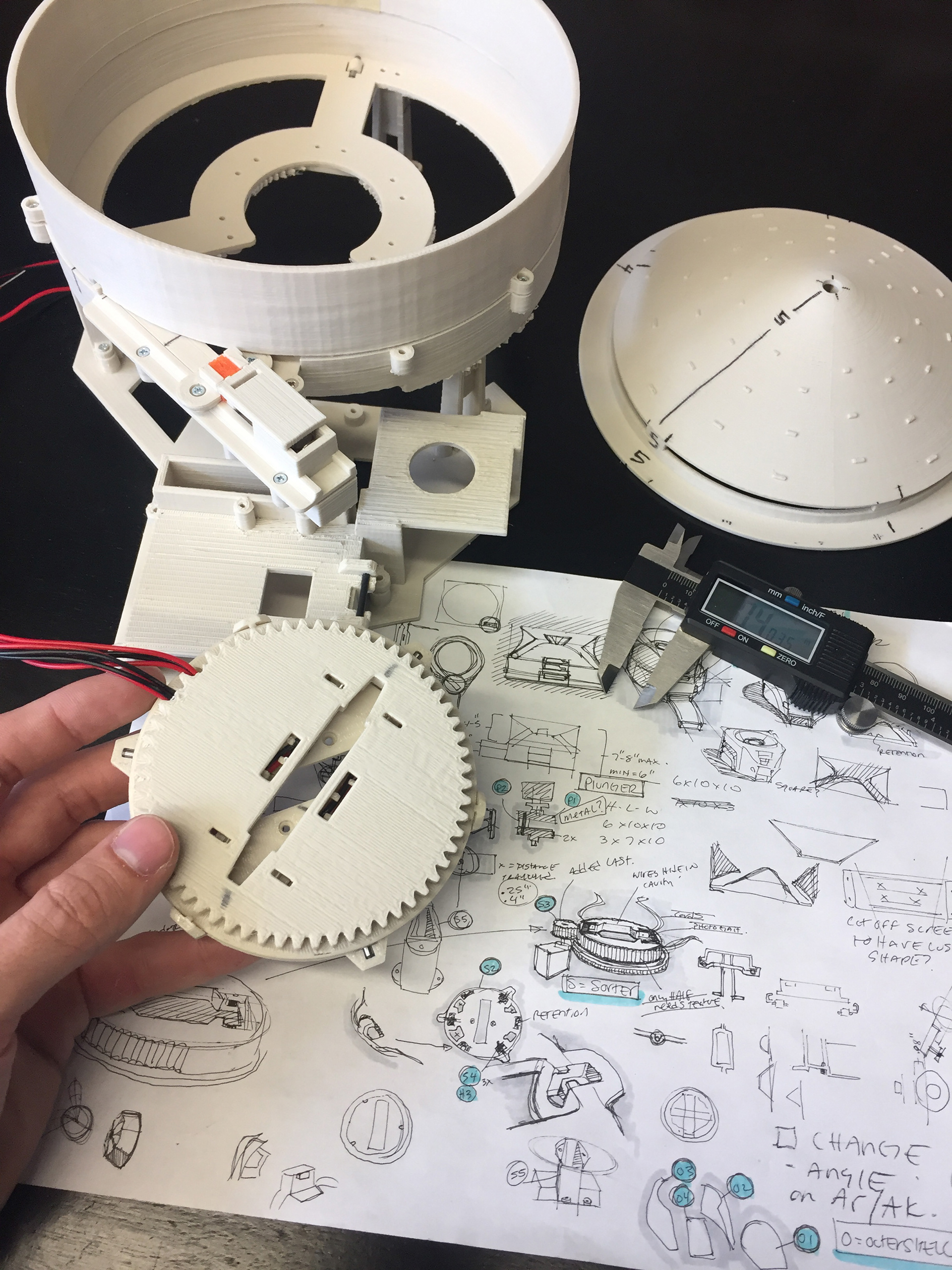

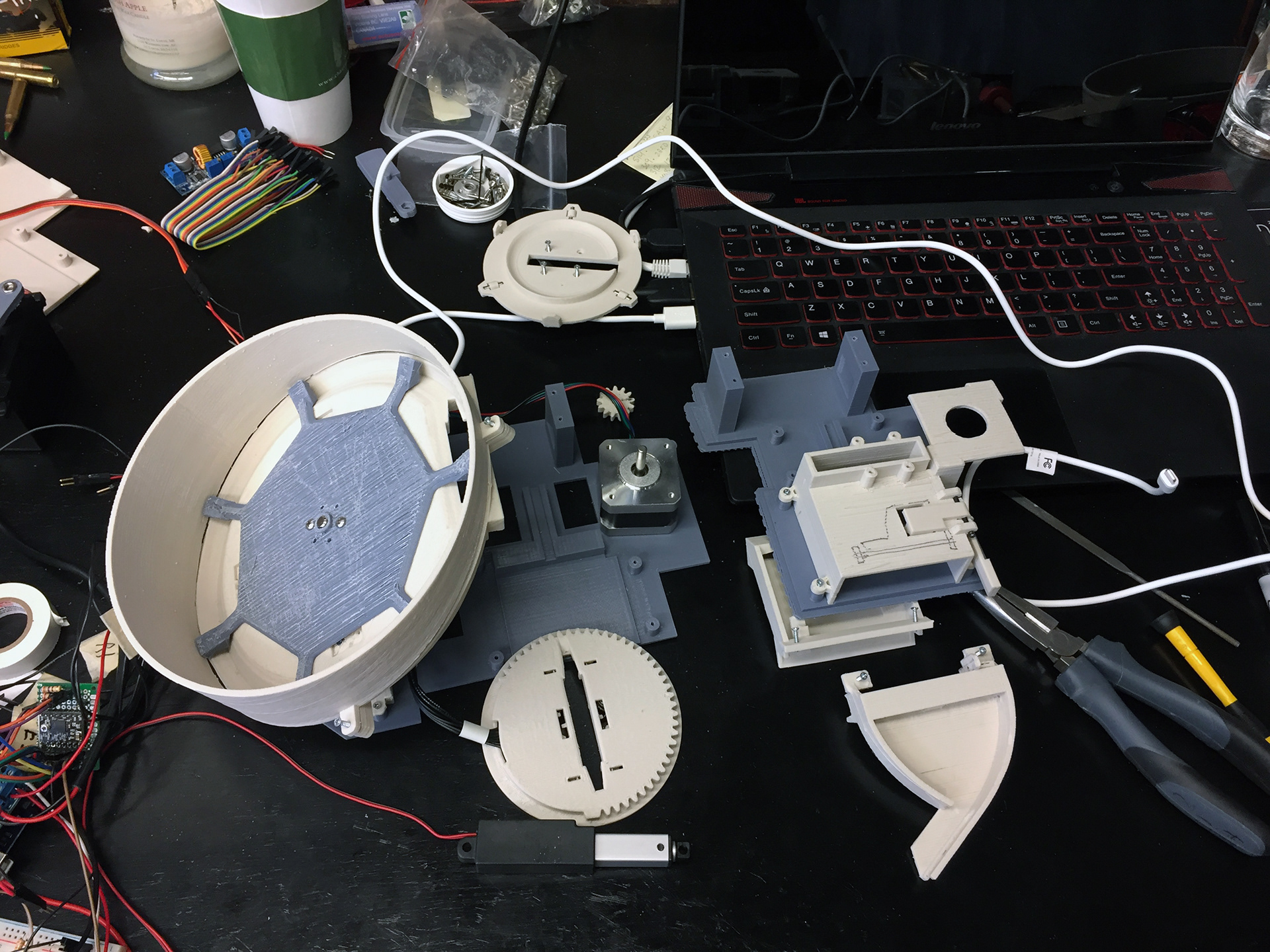

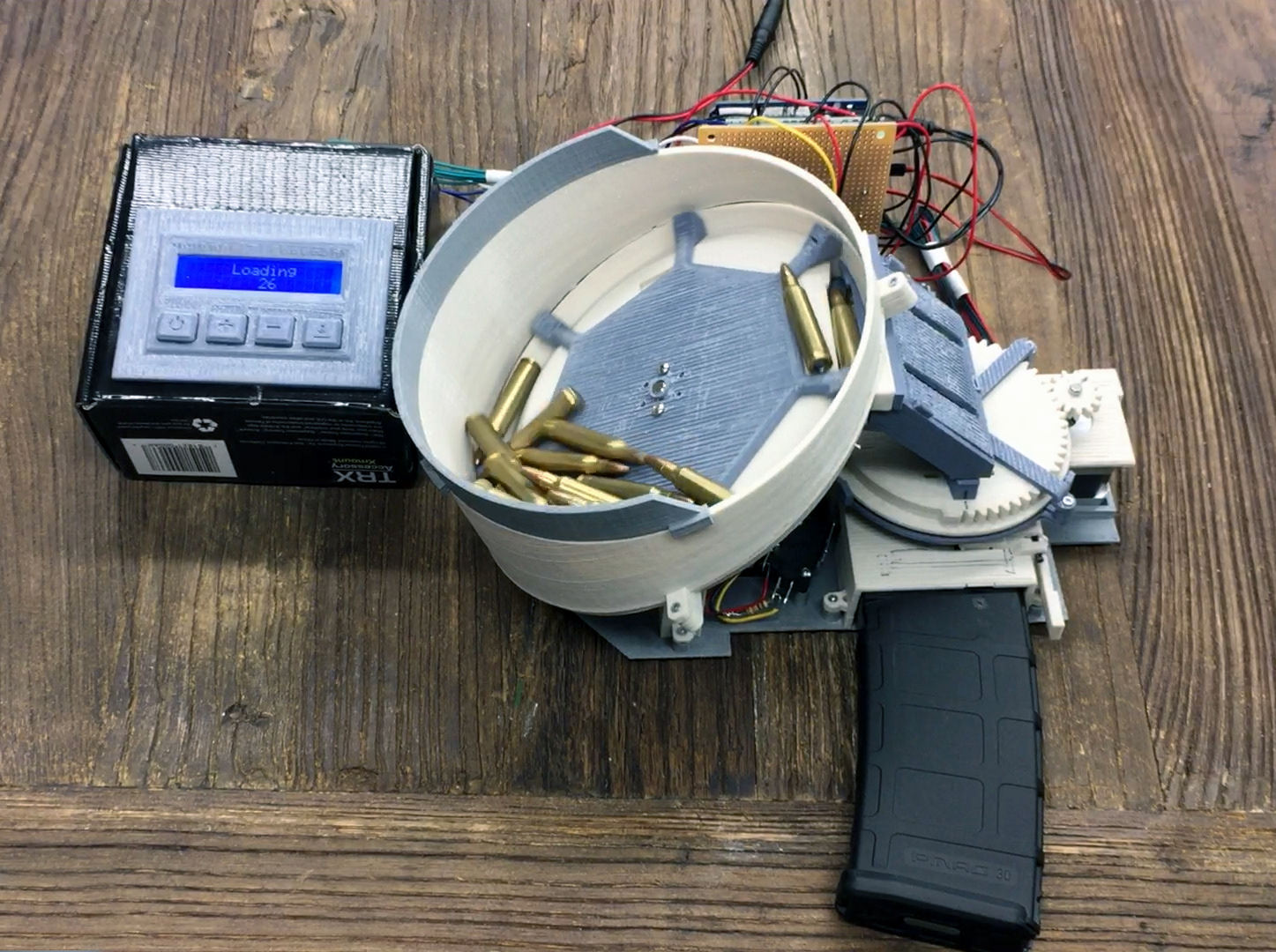

The project timeline for this was 6 months, It ended up taking a little over 9 months to complete development. This was my first project managing a contracted electrical engineer, and I was forced to learn a lot in a very short amount of time. This project required hundreds of prototypes and every ounce of creativity I had at the time. I was extremely relived and satisficed once we delivered the working prototype and CAD for MFG.

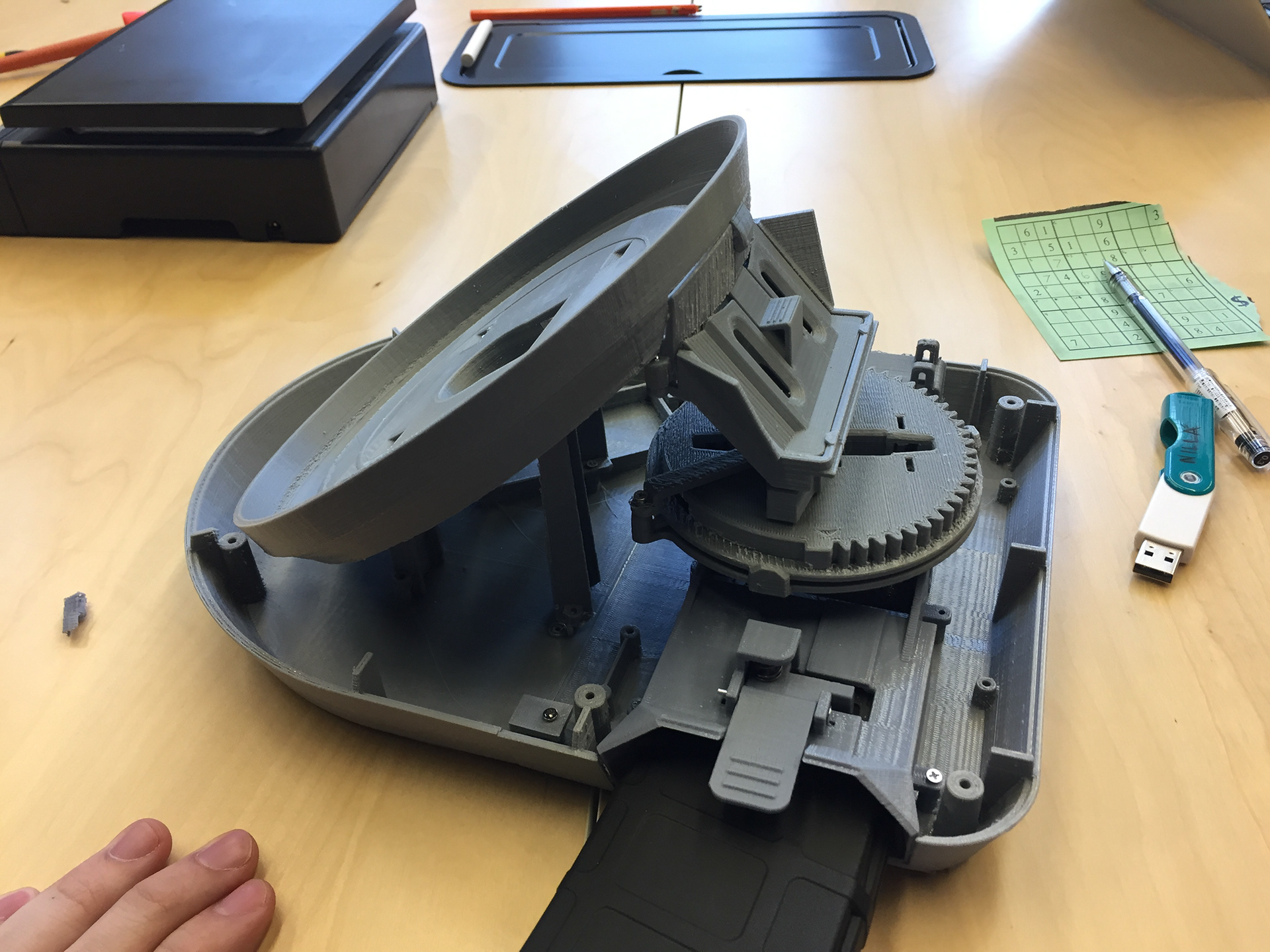

To start this project, I broke down the complexity of the design into three steps. I then created a mechanism to complete each step one after another. After combining the steps, the automatic loader could take loose ammunition and load up to a 50 round magazine.

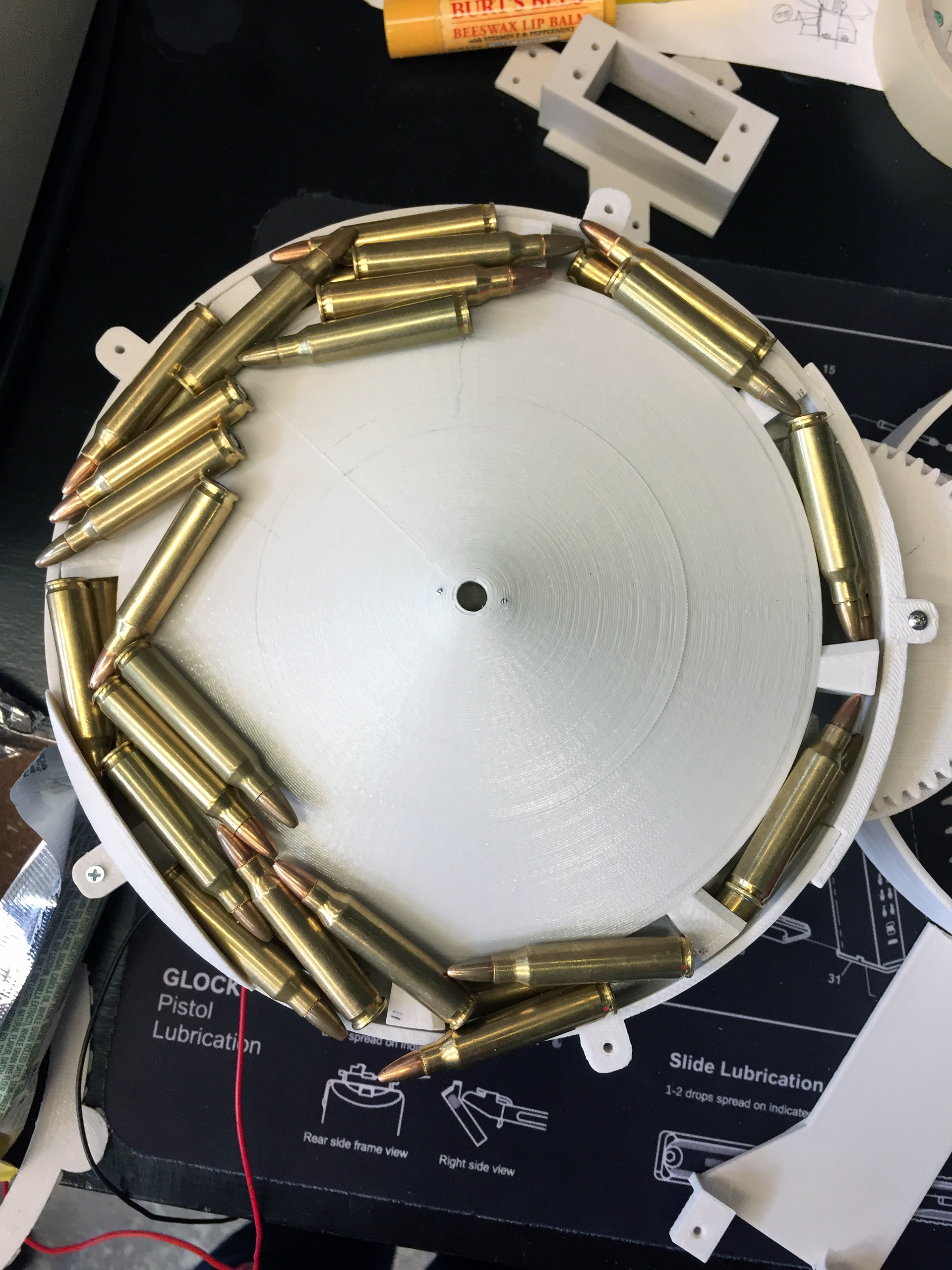

A The first steps was to contain, and sort the loose ammunition that is randomly piled together. The rounds would be organized to all be facing inline, and then handed off to step two.

B The second step takes the inline rounds, and sorts the direction the round faces. This step makes sure all of the rounds are facing a predetermined direction, and handed off to step three.

C The last step takes the sorted rounds, and physically presses them into a loaded magazine. The spring on the magazine is tough, so something strong is necessary.

Step One, was the hardest to overcome. I tried looking for inspiration everywhere I could, but countless prototypes failed to successfully complete the task. In the end the final solution took inspiration from a slot machines coin return.

Step Two, was the first to be completed. I built a spinning gate for two sets of optical sensors. This allowed the machine to detect a round, and the direction it was facing. It could then sort it quickly, accurately, and using very little space.

Step Three, was limiting. The design started more complicated than it needed to be. There were a handful of failures, which led to the realization that the loader would need a much stronger force to load a round. This led to sourcing a linear actuator to complete the task.